Binder Jetting Vs Laser Sintering . The key difference in binder jetting is that there is no heat involved in the printing process. In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Learn about the differences between these two 3d printing technologies. By andrew klein, exone director of research & development. Depending on volume in layer (>30 s) ≥15. Xometry offers sls and dmls, which are both powder bed fusion. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. This article explores exone metals and how binder jetting 3d printing for metals compares to other metal additive manufacturing. Better than casting, pm and binder but usually worse than forged.

from www.metal-am.com

In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed. The key difference in binder jetting is that there is no heat involved in the printing process. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Xometry offers sls and dmls, which are both powder bed fusion. Better than casting, pm and binder but usually worse than forged. This article explores exone metals and how binder jetting 3d printing for metals compares to other metal additive manufacturing. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. Depending on volume in layer (>30 s) ≥15. Learn about the differences between these two 3d printing technologies. By andrew klein, exone director of research & development.

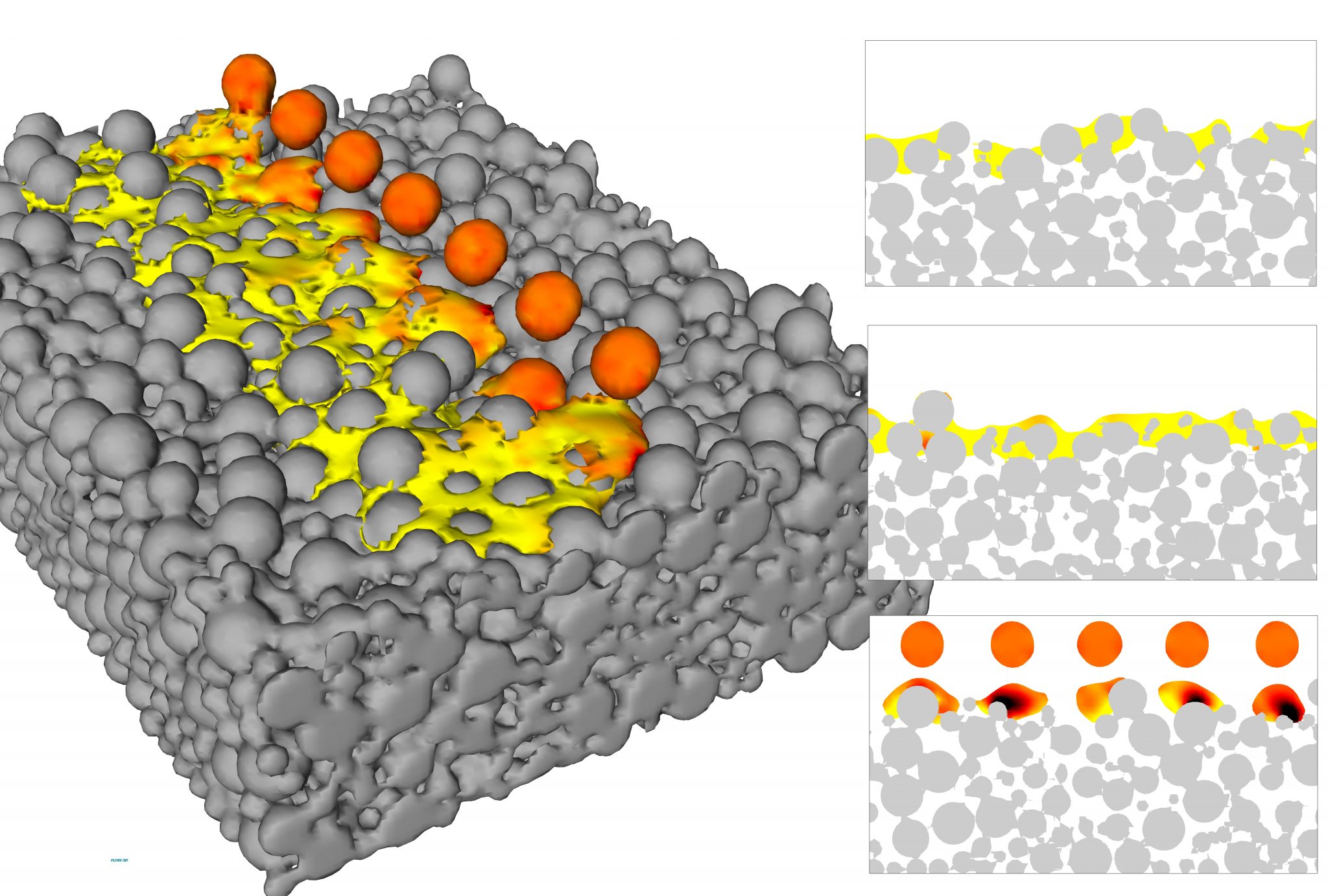

CFD simulation for metal Additive Manufacturing Applications in laser

Binder Jetting Vs Laser Sintering Xometry offers sls and dmls, which are both powder bed fusion. The key difference in binder jetting is that there is no heat involved in the printing process. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. By andrew klein, exone director of research & development. Depending on volume in layer (>30 s) ≥15. Learn about the differences between these two 3d printing technologies. This article explores exone metals and how binder jetting 3d printing for metals compares to other metal additive manufacturing. Better than casting, pm and binder but usually worse than forged. Xometry offers sls and dmls, which are both powder bed fusion. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed.

From www.scribd.com

Binder Jetting AM Process PDF Binder Jetting Vs Laser Sintering Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Better than casting, pm and binder but usually worse than forged. By andrew klein, exone director of research & development. Learn about the differences between these two 3d printing technologies. In the pbf techniques, thermal energy — applied by a laser. Binder Jetting Vs Laser Sintering.

From www.youtube.com

Sintered Vs. Green Parts in Binder Jetting YouTube Binder Jetting Vs Laser Sintering By andrew klein, exone director of research & development. Depending on volume in layer (>30 s) ≥15. In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable. Binder Jetting Vs Laser Sintering.

From www.mdpi.com

JMMP Free FullText A Review on Binder Jet Additive Manufacturing Binder Jetting Vs Laser Sintering In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed. This article explores exone metals and how binder jetting 3d printing for metals compares to other metal additive manufacturing. Learn about the differences between these two 3d printing technologies. Better. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Binder Jetting Vs Laser Sintering Better than casting, pm and binder but usually worse than forged. Learn about the differences between these two 3d printing technologies. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Depending. Binder Jetting Vs Laser Sintering.

From www.researchgate.net

Illustration of the seven types of 3D printing technologies; namely Vat Binder Jetting Vs Laser Sintering Better than casting, pm and binder but usually worse than forged. By andrew klein, exone director of research & development. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Depending on volume in layer (>30 s) ≥15. In the pbf techniques, thermal energy — applied by a laser in slm. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Thinking about metal Binder Jetting or FFF? Here is (almost) everything Binder Jetting Vs Laser Sintering Learn about the differences between these two 3d printing technologies. The key difference in binder jetting is that there is no heat involved in the printing process. By andrew klein, exone director of research & development. Xometry offers sls and dmls, which are both powder bed fusion. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Binder Jetting Vs Laser Sintering The key difference in binder jetting is that there is no heat involved in the printing process. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. Learn about the differences between these two 3d printing technologies. Depending on volume in layer (>30 s) ≥15. This article explores exone metals and. Binder Jetting Vs Laser Sintering.

From www.exone.com

ExOne Binder JettingTechnologie Binder Jetting Vs Laser Sintering Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. The key difference in binder jetting is that there is no heat involved in the printing process. Learn about the differences between these two 3d printing technologies. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Binder Jetting Vs Laser Sintering Better than casting, pm and binder but usually worse than forged. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. Xometry offers sls and dmls, which are both powder bed fusion.. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Effective metal powder specifications for Binder Jet Additive Manufacturing Binder Jetting Vs Laser Sintering The key difference in binder jetting is that there is no heat involved in the printing process. Xometry offers sls and dmls, which are both powder bed fusion. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. By andrew klein, exone director of research & development. Without a doubt, binder. Binder Jetting Vs Laser Sintering.

From 3dcentroamerica.com

Binder jetting 3d printing Binder Jetting Vs Laser Sintering In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed. Better than casting, pm and binder but usually worse than forged. The key difference in binder jetting is that there is no heat involved in the printing process. Binder jetting. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

CFD simulation for metal Additive Manufacturing Applications in laser Binder Jetting Vs Laser Sintering Xometry offers sls and dmls, which are both powder bed fusion. By andrew klein, exone director of research & development. The key difference in binder jetting is that there is no heat involved in the printing process. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Binder jetting (bj) builds. Binder Jetting Vs Laser Sintering.

From dreams.mii.vt.edu

Binder Jetting Design, Research, and Education for Additive Binder Jetting Vs Laser Sintering Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. This article explores exone metals and how binder jetting 3d printing for metals compares to other metal additive manufacturing. Xometry offers sls and dmls, which are both powder bed fusion. By andrew klein, exone director of research & development. Learn about. Binder Jetting Vs Laser Sintering.

From wzr.cc

3D printing of ceramics using binderjetting WZR ceramic solutions Binder Jetting Vs Laser Sintering Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed. Depending on volume in layer (>30 s) ≥15. The key difference. Binder Jetting Vs Laser Sintering.

From engineeringproductdesign.com

What is Binder Jetting and how does binder jetting work Binder Jetting Vs Laser Sintering Better than casting, pm and binder but usually worse than forged. Learn about the differences between these two 3d printing technologies. Depending on volume in layer (>30 s) ≥15. The key difference in binder jetting is that there is no heat involved in the printing process. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two. Binder Jetting Vs Laser Sintering.

From facfox.com

The Complete Guide to Binder Jetting in 3D printing FacFox Docs Binder Jetting Vs Laser Sintering The key difference in binder jetting is that there is no heat involved in the printing process. Depending on volume in layer (>30 s) ≥15. Better than casting, pm and binder but usually worse than forged. Without a doubt, binder jetting and direct metal laser sintering (dmls) are the two largest metal 3d printing solutions. Learn about the differences between. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Binder Jetting Vs Laser Sintering By andrew klein, exone director of research & development. Binder jetting (bj) builds parts by depositing a binder onto the powder, suitable for various materials, including metals, ceramics,. This article explores exone metals and how binder jetting 3d printing for metals compares to other metal additive manufacturing. In the pbf techniques, thermal energy — applied by a laser in slm. Binder Jetting Vs Laser Sintering.

From www.metal-am.com

Simufact Additive Binder Jetting workflow with sintering simulation Binder Jetting Vs Laser Sintering Learn about the differences between these two 3d printing technologies. Better than casting, pm and binder but usually worse than forged. By andrew klein, exone director of research & development. In the pbf techniques, thermal energy — applied by a laser in slm and an electron beam in ebm — is used to fuse metal powder particles in a bed.. Binder Jetting Vs Laser Sintering.